High Pressure Casting Machine Solution Expert

PRODUCT CATEGORIES

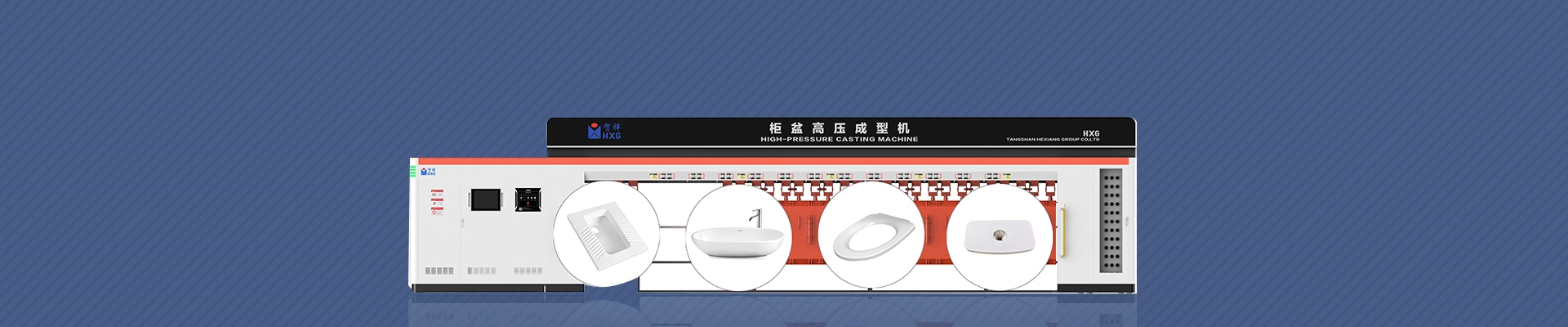

High‑Pressure Casting Machine Categories

Our High‑Pressure Casting Machines deliver exceptional precision and efficiency across multiple sanitary‑ware applications. The One‑Piece Toilet Casting line uses integrated battery benches and sling‑lift systems for seamless, high‑volume toilet bowl production. The Wash Basin Casting models feature compact, automated cells capable of casting basins, lava, and pedestals in under 20 minutes per cycle. Tailored Cistern/Tank Casting systems accommodate various flush tank designs with high consistency. Finally, the Squatting Pan Stations utilize dual‑cavity, micro‑pressure consolidation and modular lifting systems for efficient squat toilet manufacturing.

IDEAL APPLICATIONS

Modern Toilet Manufacturing Automated one‑piece toilet casting benches produce high‑quality bowls with minimal labor and compact footprints.

Wash Basin Production High-pressure cells yield basins, pedestals, and lava wash troughs within ~16‑20 minutes, optimizing throughput.

Flush Tank Casting Precision cistern casting systems ensure uniform wall thickness and leak-proof molds, ideal for consistent volume control.

Squatting Pan Fabrication Dual‑cavity systems with micro‑pressure pipelines and sling‑lift design enhance production speed and reliability.

CORE ADVANTAGES

Maximized output, energy efficiency, and precision through advanced automation, compact design, and premium component integration.

High Efficiency & Output Optimized cycle times—16–30 min—via automated sling‑lift and battery casting benches enable daily production of hundreds to thousands of units. The compact modular design boosts output while minimizing floor space.

Precision & Quality Control Integrated PLC control, micro‑pressure consolidation, and vacuum‑assisted systems guarantee tight tolerances, low porosity, and surface quality suitable for glazing and finishing.

Energy Saving & Labor Reduction Water‑tight molds play a key role in reducing drying energy, while automation significantly cuts labor intensity—aligning with smart manufacturing trends.

Modular Flexibility Systems—from wash basin cells to squat pan stations—are customizable in mold count and layout to suit specific product lines, ensuring scalability and rapid ROI.

NEWS & EVENTS

FAQS

Q1: What cycle time does it offer?

A1: Typical casting cycles range from 16 to 30 minutes, depending on product type and mold configuration.

Q2: Which products are supported?

A2: Supports one‑piece toilets, basins, cisterns, and squat pans—all within one unified high‑pressure casting platform.

Q3: How is maintenance handled?

A3: Routine tasks include hydraulic checks, mold polishing after ~200 cycles, and timely hydraulic oil replacement

CONTACT US TODAY

Have questions? Our expert team is ready to assist you!

Phone: +86‑315‑8381888 / +86‑137‑85527888